Medical Department

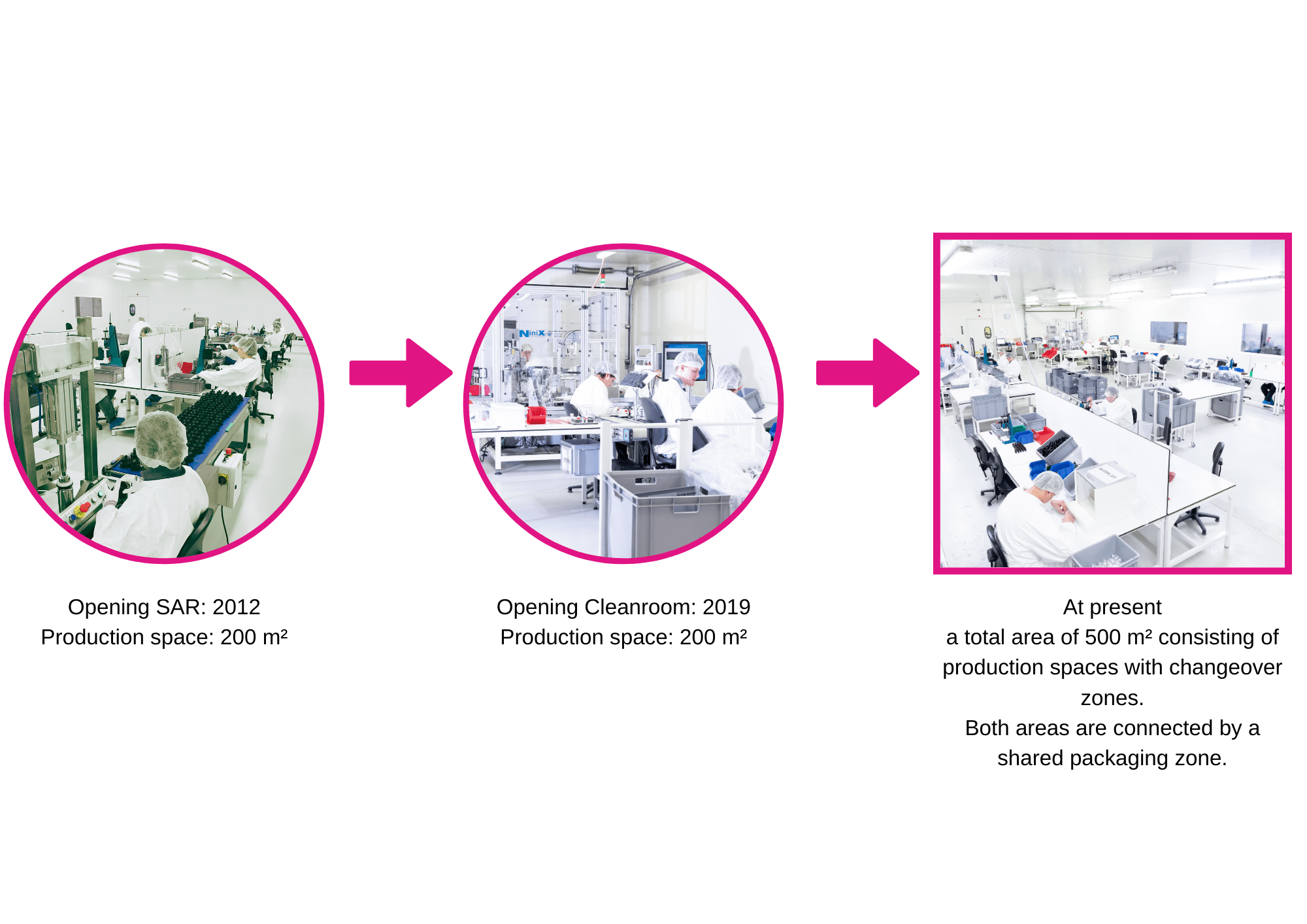

Welcome to OptimaT's Medical Department, where we, as a subcontractor, provide the assembly of various medical devices within our clean packaging zone, low dust area and cleanroom.

At OptimaT we are highly committed to a well-developed quality management system. We have ISO 9001 and ISO 14001 for all our departments. For the assembly of medical devices we have ISO 13485. In dialogue with the customer, we assess the area of application of the medical device within the MDR legislation in order to meet the necessary requirements. With our cleanroom we can produce your product in a conditioned area. Here we create the preferred environment for your production process.

As a subcontractor, our focus is on the production part within the supply chain. In this, we are unique because we are committed to both smaller production series and mass production. Moreover, our customers tell us that our experience for scaling up series sizes is a great added value for them.

Specifically for MedTech and HealthTech, we have the necessary know-how for the electrical assembly part (soldering, PCB's, cable preparation, etc.) and our production area is equipped with a spacious ESD zone.

Also filling of solid and liquid products, coding of bags and packages, labeling of bottles and tubes, palletizing of shipment boxes.... are part of our range of services.

OpitmaT is the right partner for projects within the Medical and Pharma industry and strives for total solutions.

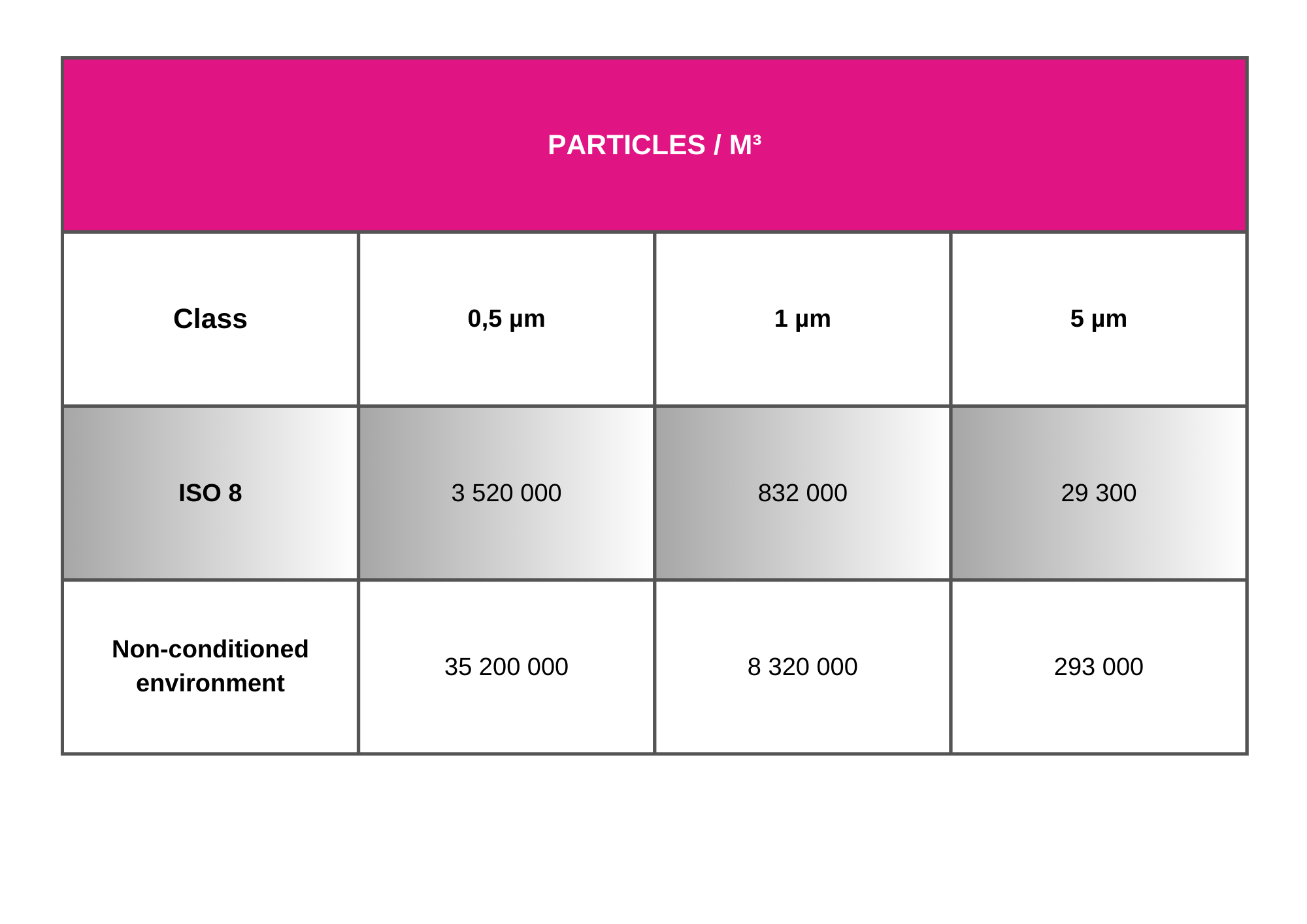

Our cleanroom is a conditioned room, class 8 validated, in which the concentration of dust particles floating in the air is limited to specified limits:

To fulfill this, we follow several procedures, similar to those in an operating room:

- Strict dresscode and dressing procedures.

- A tight cleaning schedule: daily cleaning

- Constant analysis and monitoring of working methods

- Validated room for dust particles

- Room monitored for temperature and humidity

- Adapted worktables and chairs

Your project in our Medical Department?

Discover our production possibilities and adapted spaces 'clean packaging zone, low dust area and clean room'. As an additional asset, we have the ISO 13485 for the assembly of medical devices.